"Nosen Cessna 310 Club"

#1726

My Feedback: (11)

Wow, great detail on this build. I like how you built new engine boxes, that go all the way back to the wing tube.

I never did thank for posting the, more specific info, about the carbon wing tubes that you put in place.

Still have not had the time to get into retro-fitting new tubes into my 310. Think my challenge is going to be getting the old tube out, and maintain tubing alignment.

- My plan is to make a drill bit out of tubing, that "just" fits over the current tube. Going to use the current tube as a pilot to bore all the way down into the wing.

I am hoping that this will minimize the need for a fixture, as those tubes are already running parallel ...

- will have to measure to make sure. might be able to "float" the tubes at the butt joint to take up minor (a few microns), then tied it down.

As mention, this plan is complete, and trying no to tear into too much.

I never did thank for posting the, more specific info, about the carbon wing tubes that you put in place.

Still have not had the time to get into retro-fitting new tubes into my 310. Think my challenge is going to be getting the old tube out, and maintain tubing alignment.

- My plan is to make a drill bit out of tubing, that "just" fits over the current tube. Going to use the current tube as a pilot to bore all the way down into the wing.

I am hoping that this will minimize the need for a fixture, as those tubes are already running parallel ...

- will have to measure to make sure. might be able to "float" the tubes at the butt joint to take up minor (a few microns), then tied it down.

As mention, this plan is complete, and trying no to tear into too much.

#1727

Member

Join Date: Oct 2011

Location: Waterloo, ON, CANADA

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

Wow, great detail on this build. I like how you built new engine boxes, that go all the way back to the wing tube.

I never did thank for posting the, more specific info, about the carbon wing tubes that you put in place.

Still have not had the time to get into retro-fitting new tubes into my 310. Think my challenge is going to be getting the old tube out, and maintain tubing alignment.

- My plan is to make a drill bit out of tubing, that "just" fits over the current tube. Going to use the current tube as a pilot to bore all the way down into the wing.

I am hoping that this will minimize the need for a fixture, as those tubes are already running parallel ...

- will have to measure to make sure. might be able to "float" the tubes at the butt joint to take up minor (a few microns), then tied it down.

As mention, this plan is complete, and trying no to tear into too much.

I never did thank for posting the, more specific info, about the carbon wing tubes that you put in place.

Still have not had the time to get into retro-fitting new tubes into my 310. Think my challenge is going to be getting the old tube out, and maintain tubing alignment.

- My plan is to make a drill bit out of tubing, that "just" fits over the current tube. Going to use the current tube as a pilot to bore all the way down into the wing.

I am hoping that this will minimize the need for a fixture, as those tubes are already running parallel ...

- will have to measure to make sure. might be able to "float" the tubes at the butt joint to take up minor (a few microns), then tied it down.

As mention, this plan is complete, and trying no to tear into too much.

#1728

My Feedback: (46)

Join Date: Dec 2003

Location: Chelsea,

IA

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

I am currently in the process of building a Nosen 310 from an original kit. Yep doin it old school. Well sorta. Im not using nitro engines. I do have a question for those who have built or owned one. What servos to use for surfaces. Particularly how much torque do they need to have?

#1729

Member

Join Date: Oct 2011

Location: Waterloo, ON, CANADA

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

I am currently in the process of building a Nosen 310 from an original kit. Yep doin it old school. Well sorta. Im not using nitro engines. I do have a question for those who have built or owned one. What servos to use for surfaces. Particularly how much torque do they need to have?

#1731

Member

Join Date: Oct 2011

Location: Waterloo, ON, CANADA

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

#1733

Member

Join Date: Oct 2011

Location: Waterloo, ON, CANADA

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

Well I can't believe that it has been a grueling 3 weeks since my last post..

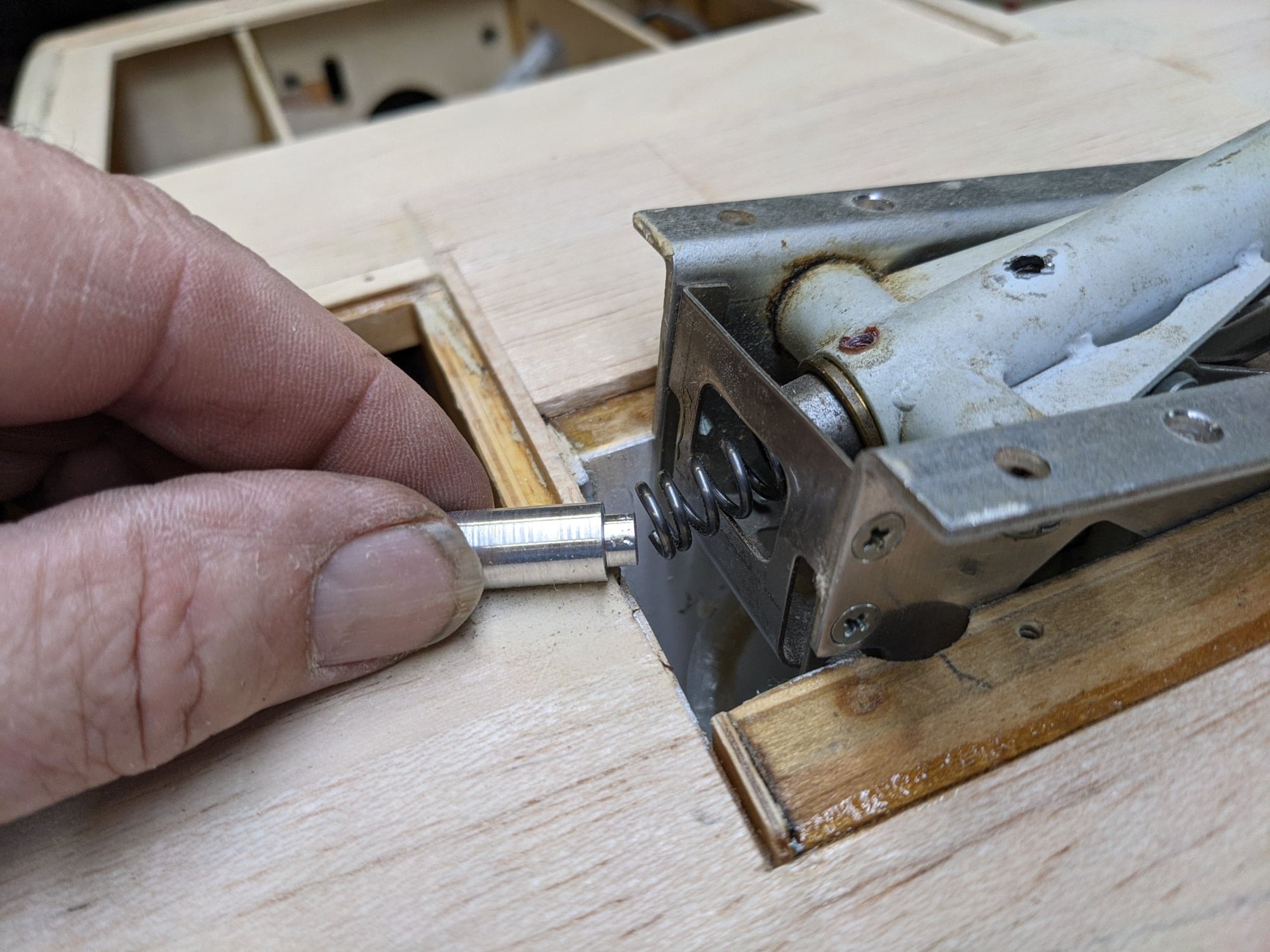

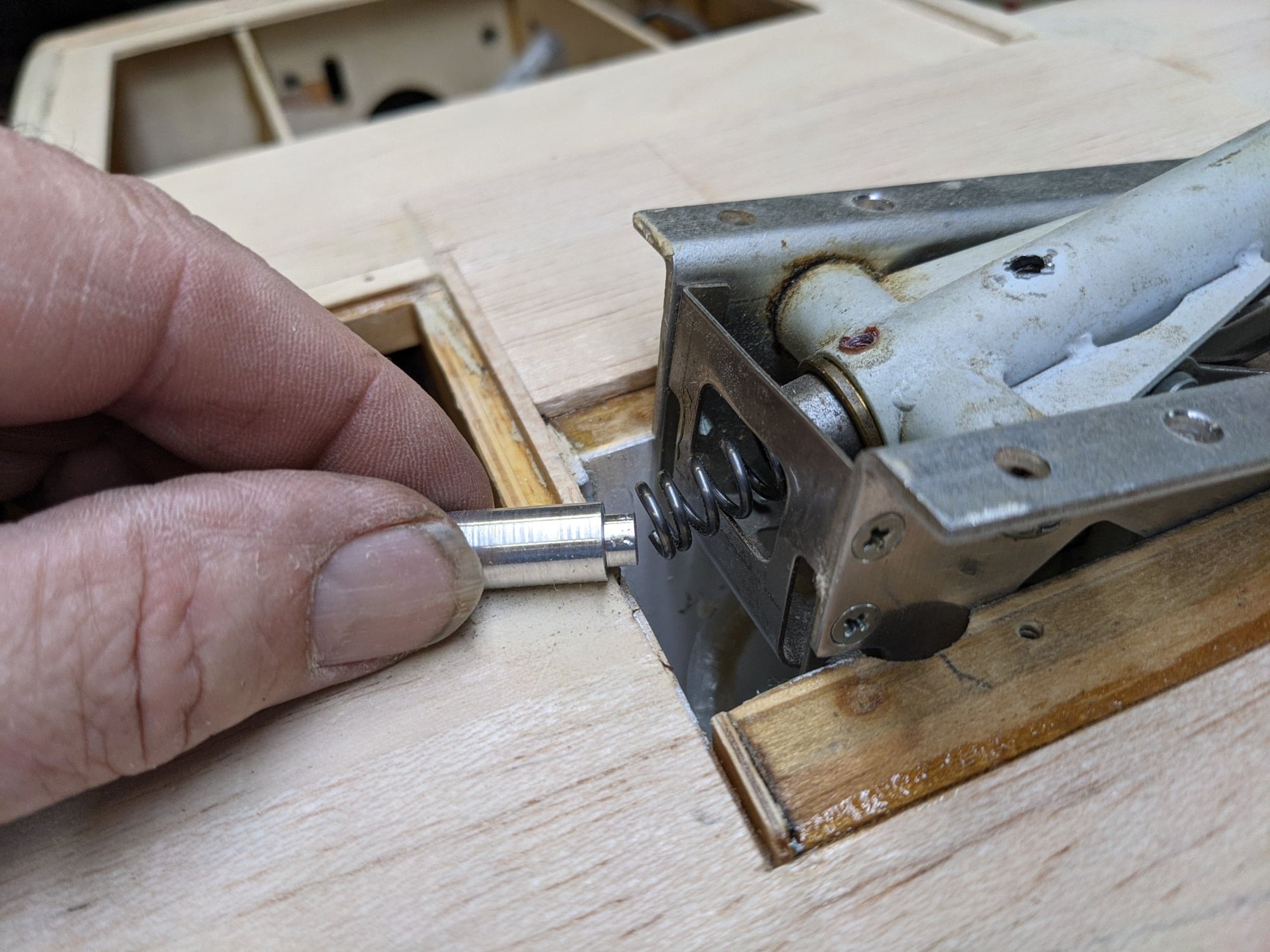

And it has been HELL.. trying to get those lousy Robart's retracts working right.. a lot of modifications.. chasing air leaks.. the nose gear and one main gear where bypassing air in the cylinders..

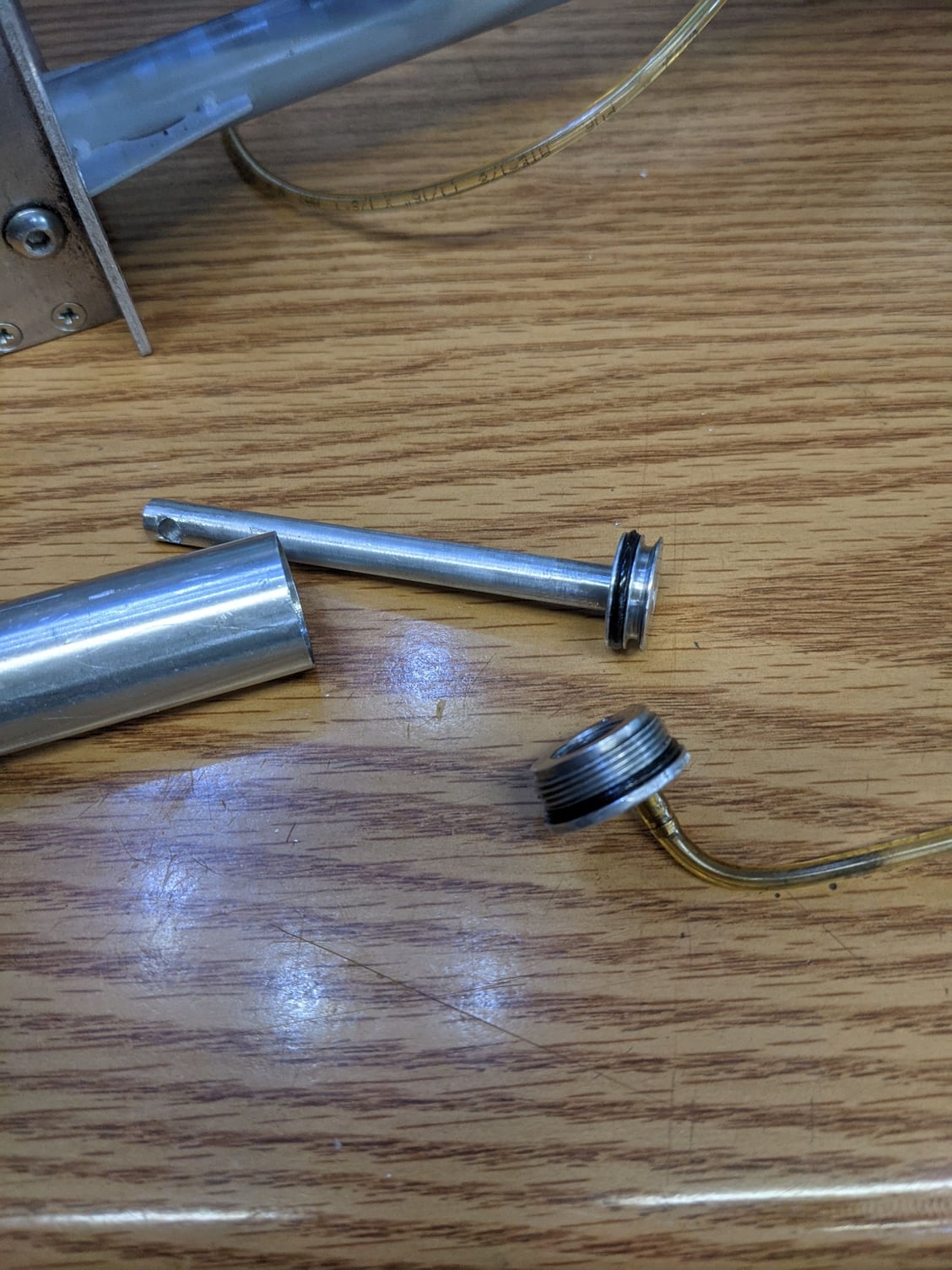

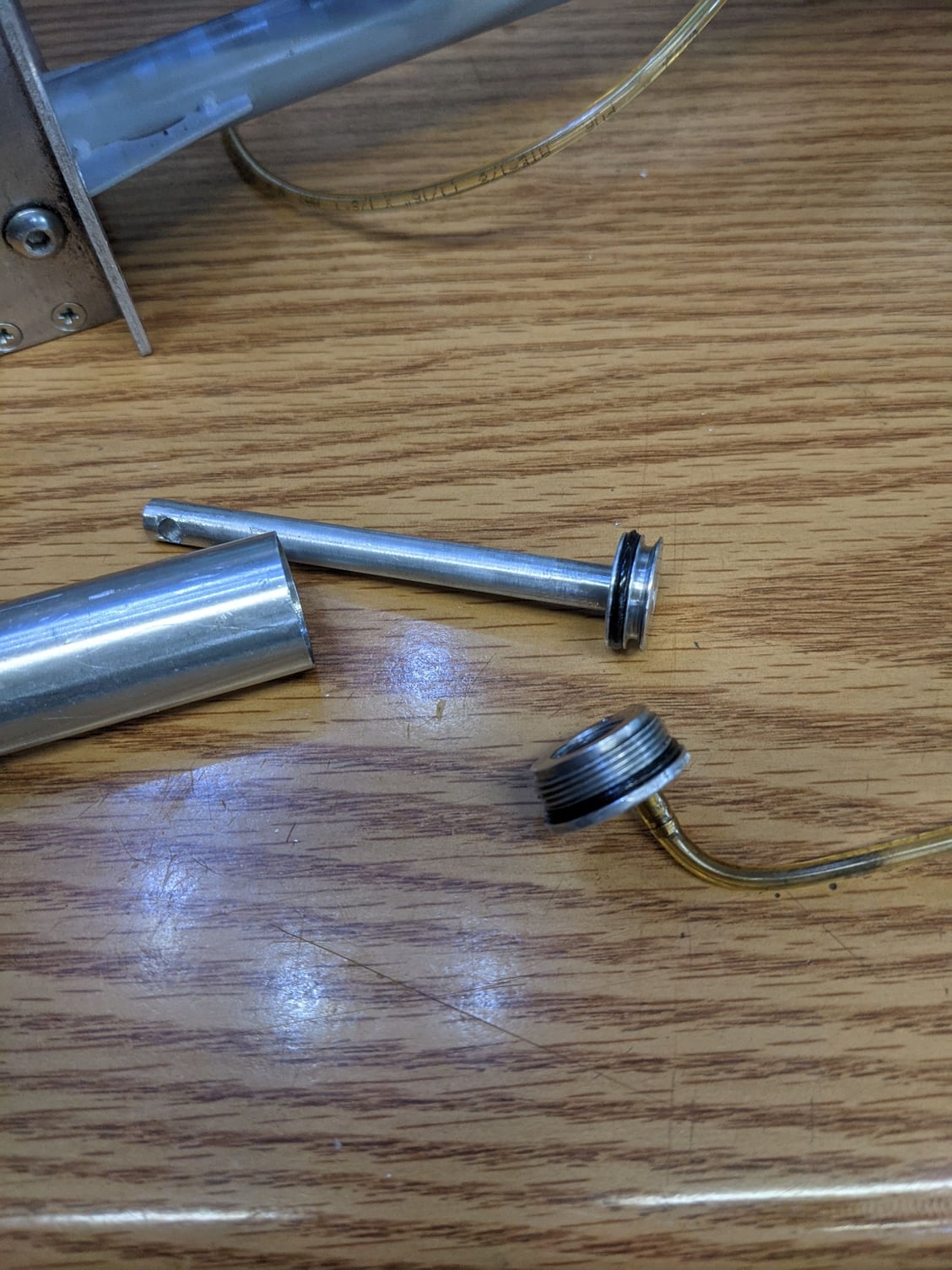

the main was not to much of a problem ,, just a new O-ring.. but the nose ,, I need to machine a new piston and rod assembly with tighter tolerances to get it to stop..

As well I had to put in two valves.. a four way for the mains due to the volume of air they used and a variable restrictor for the nose gear..

The next problem that showed up ,, the gear are specked to support 35-50 lb aircraft..

Not a bloody chance in hell... I ended up machining a plug to go under the spring to put it under tension.. this finally solved the problem of supporting the 35 lb aircraft..

In a bench test this morning.. with two large air tanks.. at 100 psi.. I could get 23 cycles of the gear and it worked reliably down to 20 psi..

all three gear go up and down at the same time ,, and not too bad for speed.. a bit fast for a scale look ,, but I can live with it..

now time to finish the re-construction...

And it has been HELL.. trying to get those lousy Robart's retracts working right.. a lot of modifications.. chasing air leaks.. the nose gear and one main gear where bypassing air in the cylinders..

the main was not to much of a problem ,, just a new O-ring.. but the nose ,, I need to machine a new piston and rod assembly with tighter tolerances to get it to stop..

As well I had to put in two valves.. a four way for the mains due to the volume of air they used and a variable restrictor for the nose gear..

The next problem that showed up ,, the gear are specked to support 35-50 lb aircraft..

Not a bloody chance in hell... I ended up machining a plug to go under the spring to put it under tension.. this finally solved the problem of supporting the 35 lb aircraft..

In a bench test this morning.. with two large air tanks.. at 100 psi.. I could get 23 cycles of the gear and it worked reliably down to 20 psi..

all three gear go up and down at the same time ,, and not too bad for speed.. a bit fast for a scale look ,, but I can live with it..

now time to finish the re-construction...

#1734

My Feedback: (11)

Hey there, just some thoughts.

Was thinking that it highly unlikely that the tube bore has worn enough to warrant a new piston.. I assume you have check for any scoring in the tube itself. If so, dont think a new piston will solve the trick

If you do need a larger piston, have you considered a thicker o-ring. Warehouses, like McMaster, have a huge select. Might even be able to go to a bit thicker and smaller in diameter, which would stretch, and decrease the cross-section just a bit, if the thickness alone is too big a jump.

Was thinking that it highly unlikely that the tube bore has worn enough to warrant a new piston.. I assume you have check for any scoring in the tube itself. If so, dont think a new piston will solve the trick

If you do need a larger piston, have you considered a thicker o-ring. Warehouses, like McMaster, have a huge select. Might even be able to go to a bit thicker and smaller in diameter, which would stretch, and decrease the cross-section just a bit, if the thickness alone is too big a jump.

#1735

Member

Join Date: Oct 2011

Location: Waterloo, ON, CANADA

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

Hey there, just some thoughts.

Was thinking that it highly unlikely that the tube bore has worn enough to warrant a new piston.. I assume you have check for any scoring in the tube itself. If so, dont think a new piston will solve the trick

If you do need a larger piston, have you considered a thicker o-ring. Warehouses, like McMaster, have a huge select. Might even be able to go to a bit thicker and smaller in diameter, which would stretch, and decrease the cross-section just a bit, if the thickness alone is too big a jump.

Was thinking that it highly unlikely that the tube bore has worn enough to warrant a new piston.. I assume you have check for any scoring in the tube itself. If so, dont think a new piston will solve the trick

If you do need a larger piston, have you considered a thicker o-ring. Warehouses, like McMaster, have a huge select. Might even be able to go to a bit thicker and smaller in diameter, which would stretch, and decrease the cross-section just a bit, if the thickness alone is too big a jump.